Add an Intelligent Stretch Wrapping System to Your Packaging Line

Ensure your pallet loads are wrapped consistently and securely with a stretch wrapping system from PackEdge. A stretch wrapping machine must be considered if you are wrapping more than 10-15 loads per day.

There are many benefits to investing in a new stretch wrapping system from PackEdge:

- Lower labor costs and increased worker safety.

- Find significant savings in film usage.

- Consistent wrapping to reduce product damage.

- Flexible wrapping solutions.

- Ventilate loads on pallets with roping, netting or variable wrapping patterns.

- See an immediate return on your investment.

- Establish a smart manufacturing environment.

- Monitor your machine performance.

Which Type of Stretch Wrapping Machine is Right for You?

Getting the right machine is critical for managing proper load control and stretch film consumption. When you work with PackEdge, we will match the right machine to your operation’s needs so you can focus on your business knowing your equipment is aligned with your production. There are many variables and machine types to consider so we’ll work through them together.

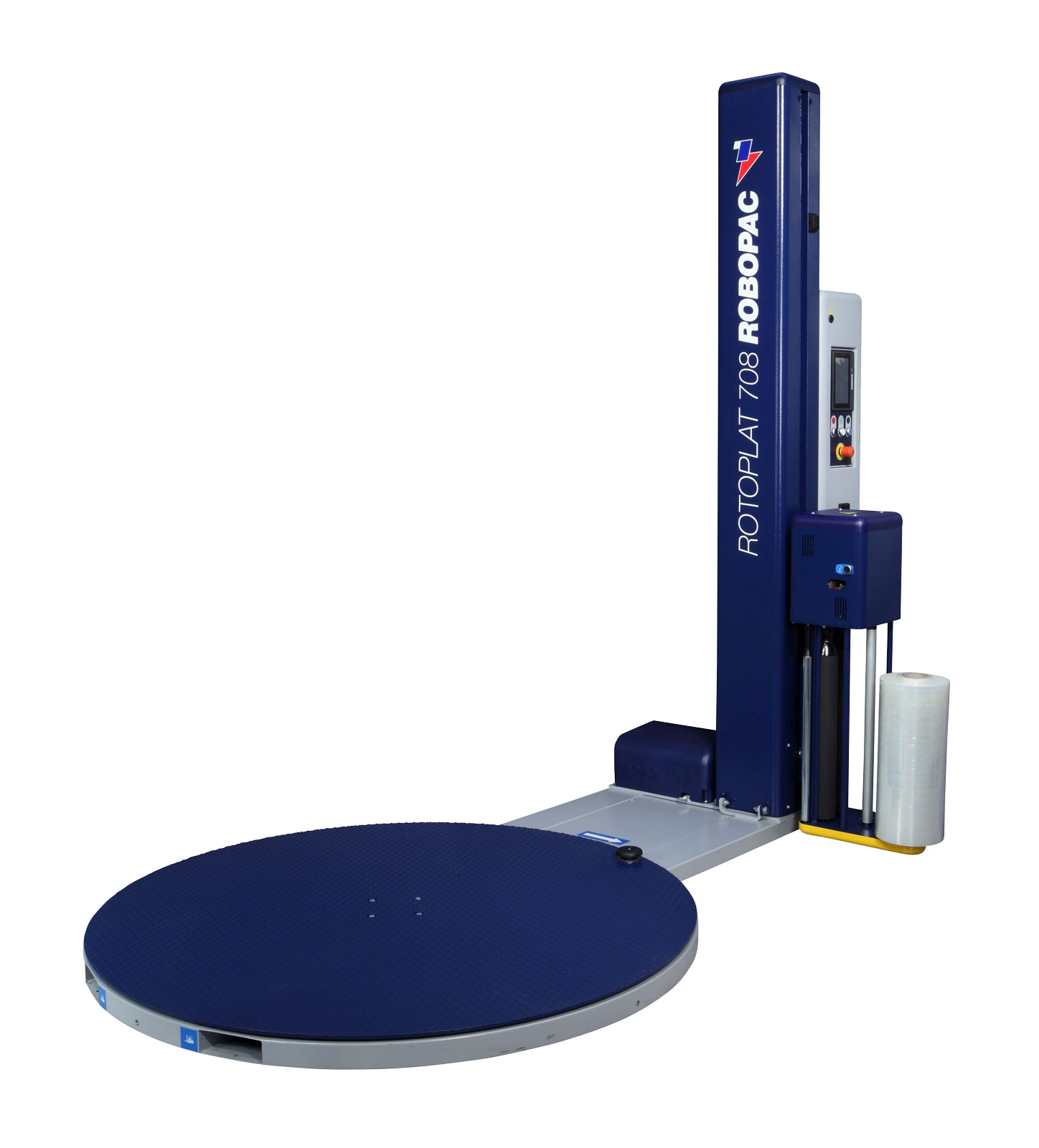

- Turntable machines

- RotaryArm systems

- Self-propelled robots

- Rotating Rings

- Horizontal Rotating Ring

- Integrated Systems

Stretch Wrapping + Technology

Modern technology is moving into your stretch wrapping operation. R-connect from Robopac USA, is a technologically advanced monitoring system that allows you to monitor your operation from anywhere on any device. Simply download the R-connect app for performance monitoring/optimization, downtime reduction, upgrade performance, predictive maintenance, remote monitoring, film usage statistics, and service ticketing.

Partner with PackEdge to establish a smart manufacturing environment. This allows you to have complete control and real-time tracking of operations and material consumption. This powerful tool provides piece of mind concerning machine operation and performance and permits better maintenance management through proactive reporting and notifications.

Cube Technology delivers exactly the right amount of film at exactly the right position with exactly the right amount of containment force.

This means you could see a reduction in stretch film cost by 30-55% along with improved load containment and reduced product damage by 40%.

Find Your Stretch Wrapping Solution

PackEdge is your premier partner for some of the finest packaging equipment and packaging products available in the market. Our experts will help you establish a smart-manufacturing environment and provide real-time data and control of your stretch wrapping operation.

PackEdge Stretch Wrapping Partner

Robopac

ROBOPAC USA is the leader in the design, production, and service of secondary packaging machines and equipment. Full lines of configurable machinery to stretch wrap, pack, palletize, erect, and seal any product in the food and beverage, personal care, pharmaceutical, dairy, distribution and most other industries are available when you work with your PackEdge team.

How Much is Your Stretch Film Really Costing You?

PackEdge goes beyond products; we work closely with you to review your load type and stretch film usage. Together we will identify opportunities to improve load control and reduce film consumption so you can spend less and use less film overall. Stay ahead of your competition.